17 years helping Canadian businesses

choose better software

SolidWorks Simulation Premium

What Is SolidWorks Simulation Premium?

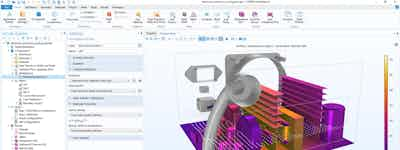

Comprehensive SOLIDWORKS Simulation suite allows you evaluate performance, improve quality and increase product innovation. Establish real-world scenarios to test products prior to manufacture for a wide range of parameters such as durability, static and dynamic response, motion of assembly, heat transfer, fluid dynamics, and plastic injection.

Who Uses SolidWorks Simulation Premium?

Cloud-based and on-premise simulation platform that enables businesses of all sizes to evaluate structural designs, dynamic loading, and composite materials.

Not sure about SolidWorks Simulation Premium?

Compare with a popular alternative

SolidWorks Simulation Premium

Reviews of SolidWorks Simulation Premium

SolidWorks simulation is quite handy!

Comments: It is overall good as long as I do not have to do anything too complicated. It is best for undergraduate projects and industrial applications.

Pros:

The bets feature of SolidWorks Simulation is that it is very very easy to use. The graphical interface makes it quite easy to understand what tool does what. Additionally the built in help and tutorials are very good to start learning the simulation process. It has all bells and whistles to do regular industrial simulations. You can apply several different loading on a part and get pretty good results with appropriate mesh.

Cons:

The major con of SolidWorks Simulation is that the base software is very resource intensive. Which means even without any simulation running it takes up quite a bit of ram of your PC. As a result, while running simulations with finer mesh a mid-tier PC often runs out of memory. Another con is that SolidWorks Simulation is not so good for research problems. It cannot handle custom element codes for advance simulation techniques such as Phase Field Modeling.

A solid FEA tool for those that don't run FEA everyday

Comments: A great program that is simple to use to gut-check our designs before sending to the broader analysis team.

Pros:

I like that the constraints are easy to set up and modify. The analysis is saved within the model itself, so rerunning and remeshing is simple.

Cons:

Edge connections for deformation or heat transfer is difficult for the mesher. Usually, we have to "work around" this by introducing a more substantial interference within the model. I wish there was a better way to do this "for simulation only" connection.

Basically all simulation tools are garbage in- garbage out unless you fully understood the problem

Comments: I am using this tool for research purpose as well as solving the daily problems

Pros:

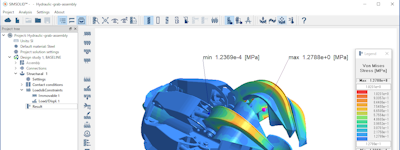

It is embedded with CAD so it is relatively easier to use. If you understand the theory of the problem you want to solve : the results that you get from SolidWorks simulation tools are as equivalent to other tools like NASTRAN, ANSYS etc. I am the advanced lead engineer at GE transportation and use this tools for vibration analysis, fatigue analysis and static analysis. I solved the real vibration problem using this tool. I am the expert in the vibration analysis theory so for me using SolidWorks is easier, less time consuming than other software like ANSYS, ABAQUS and NASTRAN. I have used ANSYS and NASTRAN in the past but I like SolidWorks Simulation most because you can easily edit the geometry in SolidWorks. Basically the only weak part of SolidWorks Simulation is mesh optimization , it doesn't have that much as it just use tetrahedral element for solid meshing but you need to be aware that mesh optimization is not only the thing through which you get the results what you want. You need to fully understand the problem and only use the simulation as a solver. For example you need to the literature survey and define the problem and data related to the problem first.

Cons:

I think SolidWorks has less strength in fatigue analysis. It has only the stress life approach and it will calculate the fatigue life based on the entered SN Curve. The other problem is: it has just a 5000 data point limit. You cannot enter more than 5000 data input curve for any analysis . It might be the huge problem. For example, if you have a signal of 5 sec time series and the signal is sampled at 1khz , you cannot enter more than 0.5sec time series that might be the issue for analyst . It would be great if they increase the input data limit and especially if they work more in the contact issue in the linear dynamic analysis. They should introduce bolt connector , no penetration/penetration contact , interference fit contact , sliding contact in the dynamic analysis . These contacts are really creating the inferiority of the software as compared to other tools like ANSYS and ABAQUS. The other thing I don't like about this software is they don't have frequency response function tool. If you want to correlate your experimental data with the simulation tool you need to have a frequency response function as FRF is the first measured quantity from the experiment. Try not to be confuse FRF with harmonic response analysis . FRF is ratio of output to input in frequency domain whereas harmonic analysis in SolidWorks is just the maximum amplitude response at the excitation frequencies range.

Really helpful software

Comments: I have been using SolidWorks for about four years and am very impressed with it. This software has streamlined my workflow and I find it easy to use. The customer service is excellent, and I have never had any problems with the software. I would recommend it to others.

Pros:

The advantage of using SolidWorks Simulation is that some users may find it very useful to understand how a component or assembly will behave in a particular configuration. It also allows users to discover assemblies by exploding, unexploding, and hiding parts from viewing capabilities. In addition, the dimensions of the 3D CAD model are automatically according to industry standards.

Cons:

While the downside is that users may find it more time consuming and more expensive than using other simple model. Additionally, SolidWorks Simulation can be difficult to use to create large and complex models, as it requires a high level of expertise and familiarity with the software.

Solidworks, an engineer's friend!

Comments: Overall, my experience was a pleasant one. I enjoyed simulating using it, just as much as I enjoyed using Solidworks to draw the simulation file.

Pros:

Amongst my first CAD software ever, it was easy to use and learn, a heaven for young aspiring engineers to get a feel for the 3D CAD world and use it to start designing their ideas and projects. With a huge library to choose from for different bolts, metals, and other design related options, Solidworks is an ideal software, and to pair that with its simulation capability provided by Simulation Premium, it becomes a hard act to follow as they say! An advanced simulation software that can solve practically any properly setup simulation whether linear or nonlinear, with good merit and a reasonable result.

Cons:

Sometimes the errors aren't as detailed as one would hope, and it is thus difficult for a beginner to find out exactly where he or she went wrong.

Advantage of using SolidWorks Simulation Premium

Comments: When i doing my projects this is one of most important software for me. As a mechanical engineering undergraduate i have design many prototypes and i had to analyse those project. This real time simulation is very useful for success my projects.

Pros:

Real time simulation UserFriendly Stress analysis Vibration analysis

Cons:

This is one of best software that i had during my university studies. I did not have any issues when i using this.

Great analysis tool

Comments: We use the simulation add-in to solve problems in designing turbo-machinery. It is an effective tool to solve natural frequency resonance, structural, flow, and thermal problems in our machine designs.

Pros:

One stop shop for modeling and analysis. Very intuitive and quick to learn.

Cons:

Older versions had limited meshing capability. This has gotten better, but still could be improved.

Amazing experience, I recommend this software

Pros:

It is the perfect tool to your projects as an engineer, architect or industrial designer. You can perform fluid simulations, including not only water and air (I performed simulataions with oil). Also, there are simulations for motions, forces and structures. It is so useful to reduce time in calculations and improve your designs reducing your factor of safety. These simulations are very close to reality because the software includes variations due to model material, surface and geometry.

Cons:

I did not find many problems with this software. Perhaps, solidworks must include a lite version to do fast reviews of your models and simulations. Just in the case, you need check simulation results or verify something in blueprints.

SolidWorks Simulation is today a complement of solidworks, is an application that is evolving

Comments: With SolidWorks Simulation I have carried out works of simulation of resistance of materials, mechanical interactions, fluids and heat transfer.

Pros:

SolidWorks Simulation has grown steadily, is a complement of solidworks, comes with the package and is very useful to test the designs.

Cons:

SolidWorks Simulation generates reports whose presentation still leaves much to be desired, for simulations using the FEM method, it would be interesting to use other methods of analysis such as BEM, and a more intuitive application to work with external simulators such as matlab is desirable.

Excellent software

Pros:

As an engineer, I found so useful SolidWorks simulation. It helps you to develop calculations related to fluid motion (including thermodynamics) and stress/deformation in your designs. So, you can correct or improve materials, dimensions, geomeotry or mechanisms in order to have a better design. It is simple and easy, you just need knowledge in mechanical design and thermodynamics. Also you can simulate motion using a library and templates that SolidWorks has.

Cons:

I had some troubles trying to view my results in other software. I think theremust be a lite versión in order to just check results and basic characteristics

good review for the solid works program

Pros:

have many functions almost all the functions needed for the any project

Cons:

it is so heavy on the laptop and makes it lag

Very powerful simulation package.

Comments: Using simulation premium was similar to standard simulation, but it allowed for greater functionality.

Pros:

This software contained extremely powerful simulation toolboxes that were needed for a project, such as non-linear and dynamic modeling.

Cons:

This software had much more functionality than was required for our purposes. It was too complex.

SolidWorks Simulation Premium Review

Comments: My overall experience with Solidworks simulation is very positive. Although it has many issues, it is still the best software to run simulations on and is the most user friendly experience.

Pros:

It is very easy to import one's model to run simulations such as Finite Element Analysis. Solidworks also generates very comprehensive test reports so the user can focus on the study they are running and less of the final report.

Cons:

While the software has many good features for running simulation studies, it can be very slow to generate final results. The software can also crash on users causing them to have to set up their study again.

Excellent package for Designers, inadequate for Pro users

Comments: Overall, if you are new or have limited FEA experience, you will be happy with it. It's good value for money for most applications and companies.

Pros:

I have been using SW Simulation package for over 10 years now and have used it wide variety of simulations (Static, Dynamic, Linear, Non-Linear, Random Fatigue, Thermal Cycle Fatigue). Pros: 1. Integration with SW CAD enables you to make quick changes and run what-if scenarios 2. Easy for entry-level MEs or Designers to understand and use 3. Tutorials are well written 4. Works 90% of the time with default settings so MEs can focus on the design instead of sim settings and parameters

Cons:

1. Not able to scale with hardware. eg you dont gain any improvement in solution time even if you use HPCs 2. Non-linear solver i snot as robust as other packages such as Abaqus or Ansys 3. Does not have low cycle fatigue capability 4. Does not have viscoeplastic material model 5. Does not have gasket element 6. Errors are difficult to understand and debug

A FEA tool for Every Design Engineer

Comments: Since SolidWorks Simulation Premium is an integrated tool within Design environment , performance of the Design can be analysed right at the design stage instead of prototype testing thereby reducing time, materials & effortsThe failure locations can be predicted & necessary design change actions can be taken

Pros:

SolidWorks Simulation User interface is by far the best for Design Engineer to setup their analysis . The integrations with Design Interface is seamless wherein any Design Changes are updated in analysis thereby cutting short the need to resetup the analysis again

Cons:

The least liked about the Solidworks Simulation is type of elements available & nonlinear solving capabilities

It's very nice software for machine design , very simple to use excellent user interface ,

Comments: Basically I have use this software to design agriculture machinery like rotavators power harrow , trolley I have complete 8 project on this software in 4 year , I have also did simulation on this software to analyze the field problem and resolve the issue I have also use Ug NX Catia but solid works will be my first choice always

Pros:

User interface is very simple, weldment is unique feature , tool box with gears , sprocket,nut bolts is very easy to import , sheet metal module is also very nice , simulation is also simple and easy to use overall nice product with small investment

Cons:

Some time reference of the part get broken in assemly , must do something to improve, must provide the complete length along with cut grrove detail in the weldment ,meshing in simulation takes high time so must do some thing to improve these things

A top tier simulation software

Pros:

It has got loads of tests you can run on a part/assembly. I love the fact that you are allowed to fully define your test parameters. The output of the test results are pre-written as a report and this saves time. You can create animations from the various test and simulations.

Cons:

It is not easy to use. The simulation wizards should be worked upon.

Easy to Use - Increased Productivity

Pros:

The User Interface of Solidworks makes it easier to use in an efficient way that results in increased productivity. I use task scheduler to schedule the drawing generation task this helps to export drawings in various formats which otherwise is a labors task. Predefined templates and equations in Solidworks have saved my time when it comes to changing the configuration or revision of the product.

Cons:

Solidworks consume a good amount of memory when loading larger machine assemblies which cause it to crash or work slow.

An good alternative for the beginner

Comments: Overall, its a great too for anyone who wants to dip their hands into the world of simulation. You get perfect and presentable reports coupled with high contrast images that can uplift the quality of the presentation.

Pros:

It is extremely straightforward, especially comparing it to other softwares like ansys workbench, comsol and abaqus. The results are really well presented and a report can be printed which has all the essentials that i will need for any presentation.

Cons:

However, there is no option for simulation of additive manufacturing materials, for which we have to use comsol or abaqus. Also, in some cases, people have reported that the method used is a tad bit less accurate that other softwares when compared to the experimental results.

The program that gives the spirit of 3D design

Pros:

During my high school education, I met with solidworks in 3D design education. In my university education, I learned the simulation program and used it for many years. I can check that many of my designed system works immediately with this program. I can even do flow analysis. A program that is very simple to use and user friendly. A different program is currently used in the company I work for, but I am using the solidworks simulation program from time to time for my own personal work.

Cons:

I had no negative experience. a program I've used and enjoyed for many years

Solidworks Simulation

Comments: As I have stated in the pros. The software has saved time and money buy focusing the design for our prototypes and reducing the cost of prototyping multiple ideas. The software has paid for itself for sure.

Pros:

The software is very easy to use. It provides me great insight into my designs, and allows me to verify designs and ideas without creating multiple prototypes. It saves time and money. The various studies that can be run is also helpful.

Cons:

There is a steep learning curve, and I find that some users may over rely on this software. Not a knock on the software, but a caution.

Great too specially for engineers

Comments: It helped me when I was designing a vehicle prototype for a SAE competition. It's a very helpful tool and made me a better engineer.

Pros:

As a production engineer and a person that has a taste for designing vehicles prototypes, CAD softwares are extremely important. It is very visual and helps you understand the dynamics of your design. It's helpful when it comes to the selection of the right material as well.

Cons:

It has a very important learning curve, but once you pass it, it's a very powerful software and will make your life so much easier.

One of the best modelling tools and analysis software available

Comments: Its a great tool and i've used it for creating airoifl models for various analysis and also for creating models for 3D printing and also the FEM solver package

Pros:

THe fact that a new user can accustom to it easily and develop cad models which are useful for various purposes. The new analysis feature are also good for preliminary design studies. I use it for 3D priitnig model creation as well

Cons:

The FEM package isn't very competitive yet compared to ansys mechanical which has exixted for several years.

My experience is good while using this software. Very helpful in design simulation.

Comments: I do buckling analysis in a project to analyse the buckling effect on column at different end point conditions. The results was very effective. I really recommend this.

Pros:

I really like it's easy to use simulation tools based on the design and it's functionality. The results are almost correct with the theoretical results.

Cons:

Some time it lags while analysis big file or design. It has some features missing if compare to its competitor products like Ansys.

Excellent for engineering design

Pros:

In the area of engineering design, simulations are very important as they bring us closer to the final product, this software allows us to simulate finite element simulations, make fluid simulations, allows you to include many variables in your simulations to obtain in this way desired security factors. The software gives you reliability in the results.

Cons:

Solidworks simulation occupies a lot of memory, so it is necessary that it be backed by a good computer for optimal development.