17 years helping Canadian businesses

choose better software

JobBOSS²

What Is JobBOSS²?

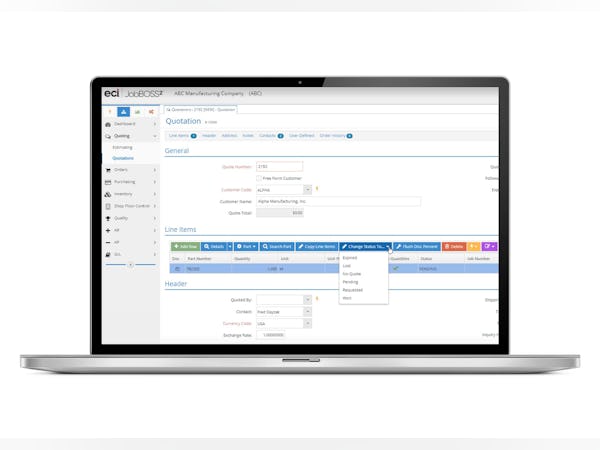

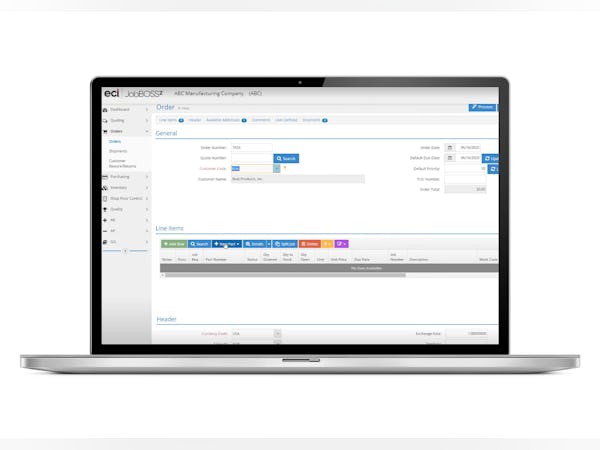

JobBOSS² promotes the profitability of scaling job shops, make-to-order manufacturers, and contract manufacturers by delivering a seamless quote-to-cash solution. A combination of JobBOSS expertise and the E2 Shop software, JobBOSS² has been helping five thousand shops increase profits by eliminating waste and streamlining operations. With an intuitive cloud-based solution and set of native mobile apps, JobBOSS² has all the tools and integrations you need to easily run your shop floor and back office operations.

Easily manage the daily demands of your job shop

• Take back valuable time with JobBOSS²s job shop

• Get real-time visibility into job profitability

• Gain accessibility, security, & efficiency with the cloud

• Become an ITAR/CMMC-compliant shop

Home-made compliance leaves companies more vulnerable to violations. Our JobBOSS² ITAR/CMMC solution is monitored by dedicated data custodians working around the clock to help you.

Who Uses JobBOSS²?

JobBOSS², formerly known as E2 Shop, helps job shops improve profitability and manage their supply chain. Our quote-to-cash solution reduces bottlenecks while improving shop floor throughput.

Not sure about JobBOSS²?

Compare with a popular alternative

JobBOSS²

Reviews of JobBOSS²

JobBOSS as an ERP

Comments: Overall we like the product and have good results with the support teams.

Pros:

JobBOSS as a standalone is good, with some nice Crystal Reports added on. What makes it great is that there are quite a few add-ons available (for Quality, CRM, etc.) , plus it it stores all of its data in a SQL format that works well with Microsoft products.

Cons:

I work mostly in the Finance/Accounting side of the business. There are some basic things that could be added in the next version upgrades.

ECI Software Solutions Response

6 years ago

Hi John, Thank you for your recent review of JobBOSS! We appreciate your feedback in making our solutions better. Would you mind sharing the basic things you referred to that could be added to our next version upgrades? We would love the opportunity to pass this along to our software dev team. Thanks again and we appreciate you as a customer! - The ECi Marketing Team

Complete company software

Comments:

The customer support was great while implementing the software and after implementation of the software.

The software exceeded our expectations.

Pros:

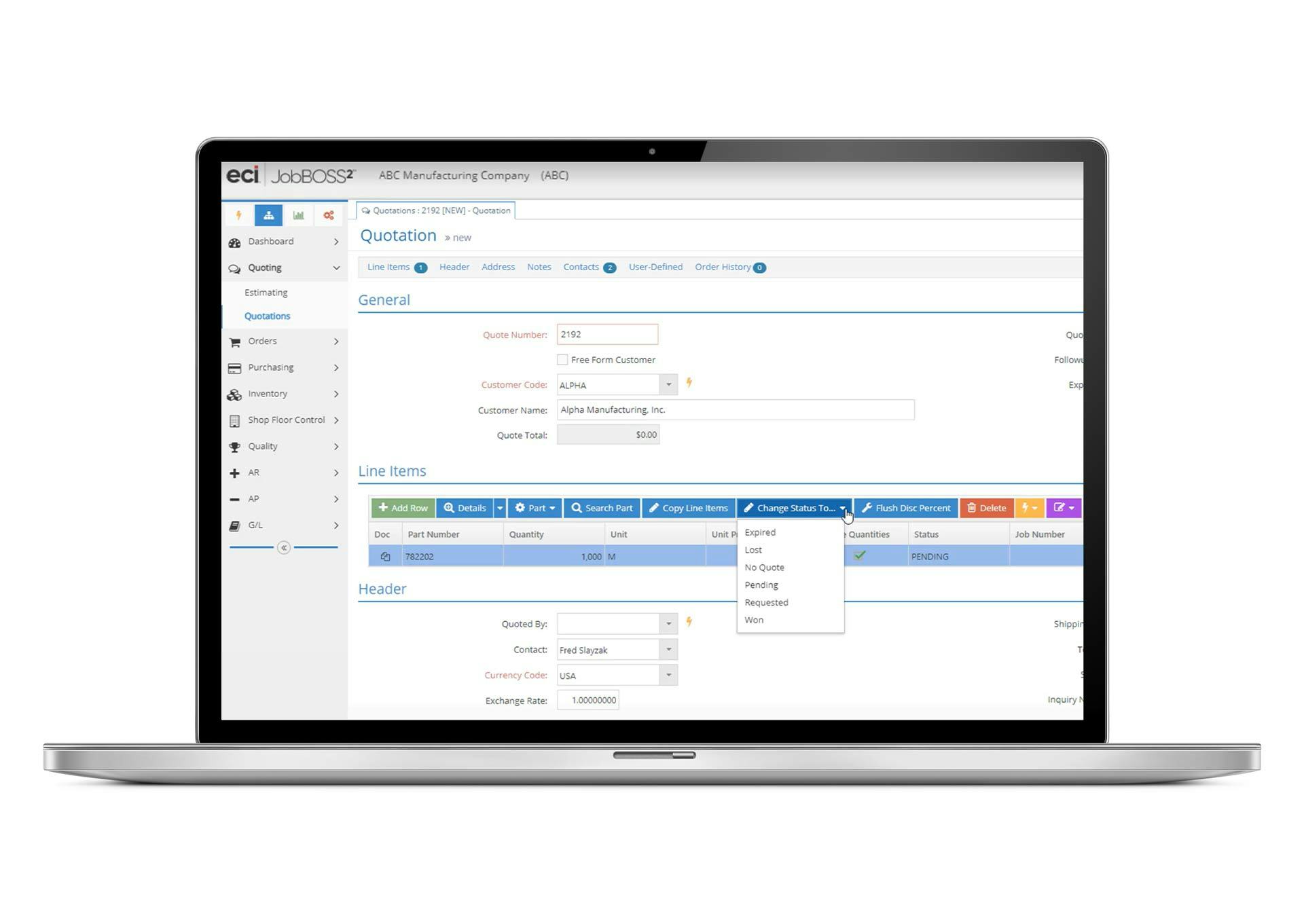

The ease of quoting parts for customers was decreased substantially. Real time reporting of the work flow in production. The ability to connect with the system offsite to give customers answers about their orders while meeting with them.

Cons:

There was a lot of data entry that had to be done to get the system working correctly for our company.

8/10: A Solid Choice for Manufacturers

Comments: Everyone at the company likes it - the shop and the offices work together in JobBOSS² and has everything we need.

Pros:

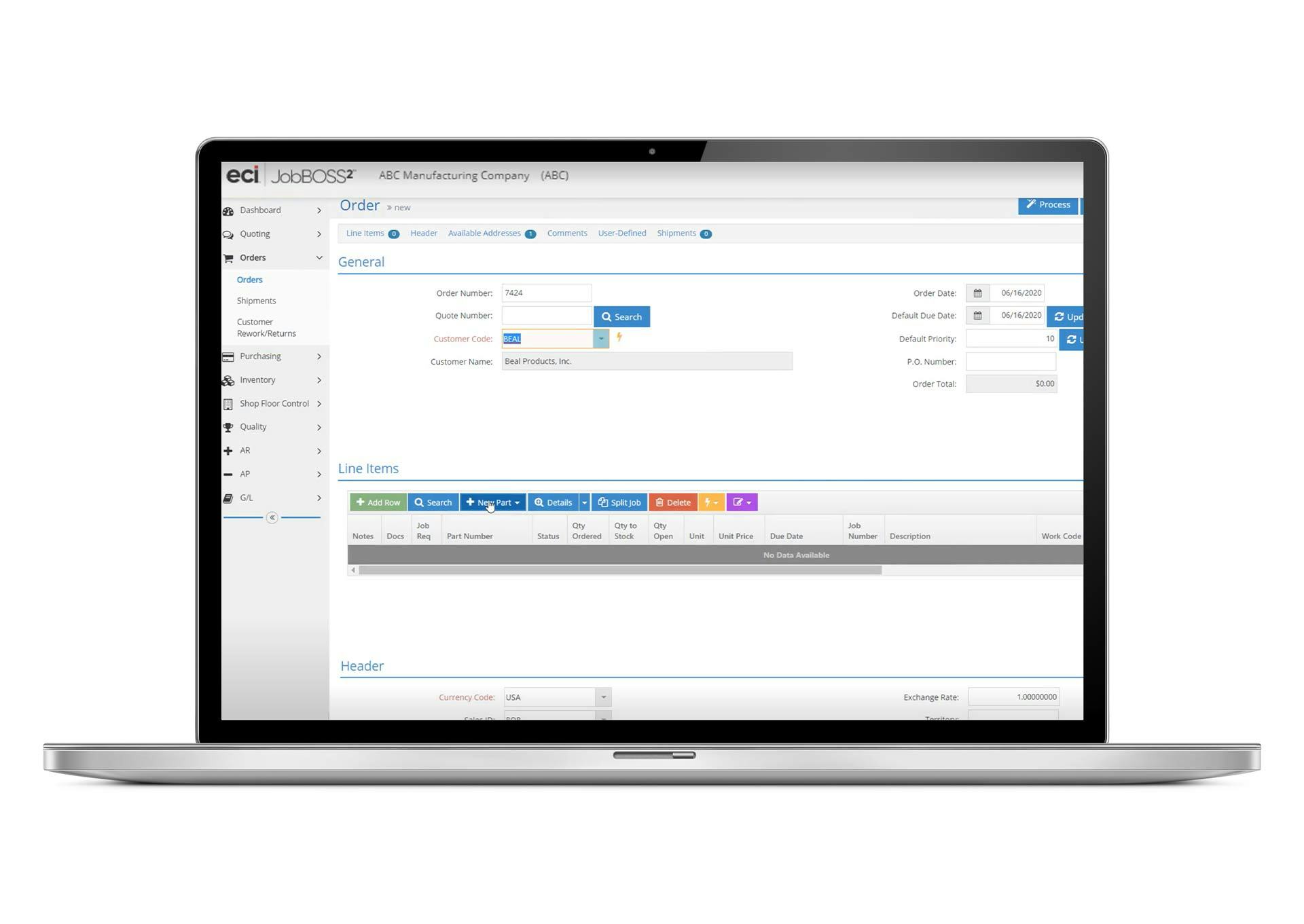

The best feature for us in JobBOSS² is how it flows through the system - from estimating to actually creating an order to shipping to receiving to billing. The workflow is very easy to understand.

Cons:

We're in the Cloud. I don't like that there is no integration to my local hard drive at the shop. So, I have to store files in 2 places. Also, there is no second security system to get important information if the system goes down.

Okay Operations Management, Terrible Customer Service

Comments: We feel the system itself is ok, but outdated for today's market. Other systems provide more digital based solutions that provide faster results more efficiently. When we voiced to them that we were switching to a new provider, they told us to get everything in order in one week and then shut down our subscription until we pay for a year contract for just 3 users. So while their system does have potential to grow, it feels they do not value their customers, no matter how loyal they have been.

Pros:

It allowed us to manage orders throughout the facility using paper-based job travelers. We also ran our invoicing and logistics through it as well.

Cons:

The system was very inflexible and could not change with the company. Training new users was also difficult. The customer service is almost non-existent. It was always very difficult to find out how to get a hold of someone if there was a question or issue.

JobBoss2/E2 Review

Pros:

Agile, fast and natively clouded. Ease of use is the best around It is not bloated and the workflow is logical for a JobShop environment.

Cons:

Quality module is a little thin. It could use custom user fields to make more robust.

Jobboss2 for Metal Manufacturing

Comments: We've been using some form of this program the 11yrs I've been with this company. In that time, I haven't had any major headaches with this program. The UI seems good. There is room for minor quality of life improvements, but overall I'm satisfied with it. I believe these minor issues can be cleared up with future updates.

Pros:

This program allows us to manage our parts, all the way from quoting, to shipping and billing. Once you learn the system, there is a lot of information available that allows you to track, schedule, and make sure your products follow all of your customers requirements. If you fully utilize what's available, you have a lot of information available to you, to make your business efficient and make sure you're making a profit on your parts.

Cons:

There is some chunkiness to the program. There are things that take more steps than necessary to find the information you need. There are some things that you can double click, and it redirects you to a different area of the program, which is good. Other things, you not only can't double click on, but it doesn't allow you to copy, necessitating manually writing it down and navigating to the other part of the program. There are a few other features I'd like to see. Things that should be available, but haven't been implemented. I feel all of these issues can be solved with future quality of life updates.

Effective Software for your Machine Shop

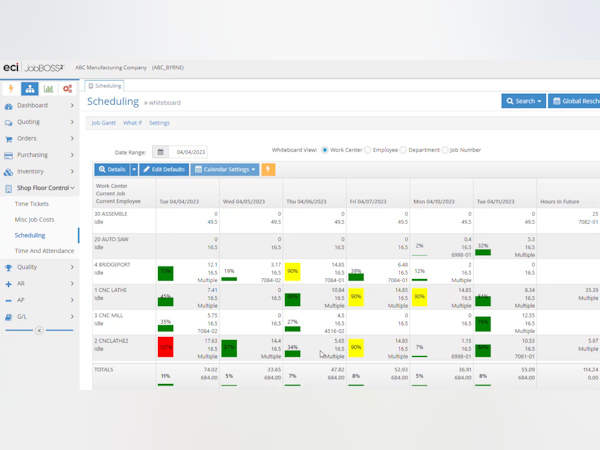

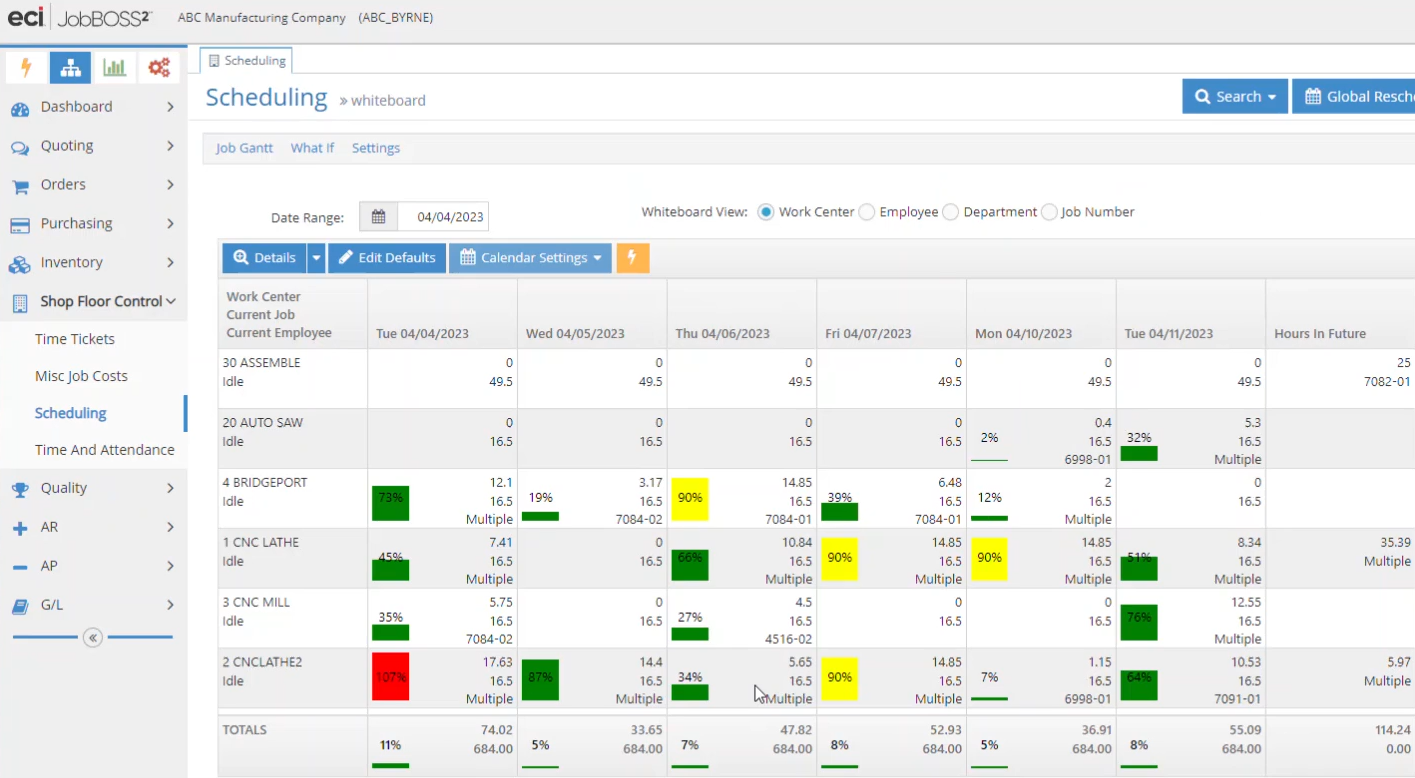

Comments: We appreciate its features for quoting, order processing, scheduling, inventory management, job tracking, and invoicing, among others. It streamlines our workflow and improves overall efficiency by centralizing key functions and providing real-time visibility into critical data.

Pros:

We like the comprehensive functionality, customization options, integration capabilities, real-time insights, user-friendly interface, and dedicated support services, all of which contribute to improved efficiency, productivity, and profitability in our manufacturing operations.

Cons:

There was a bit of a learning curve, especially for those who are not familiar with similar software or who don't have a strong background in manufacturing processes.

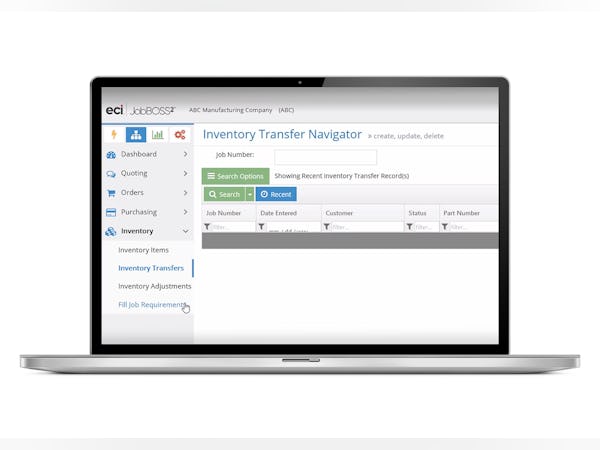

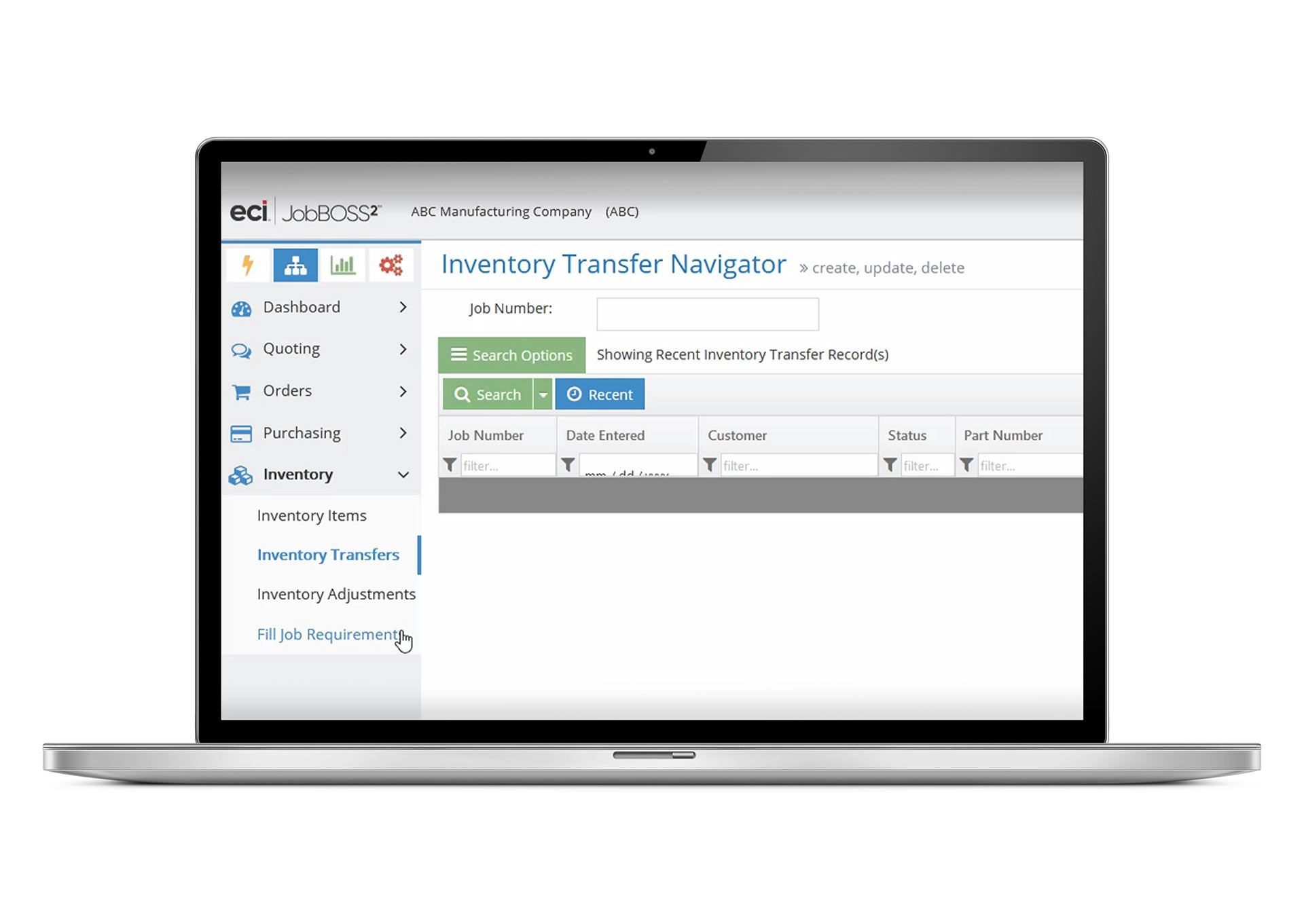

Inventory Control - Spot On

Comments: In the 8 months of using JobBoss, there was a certain learning curve as with all new software, learning how tasks are stacked to certain functionalities. Once that is learned, you can easily find what it is you are looking for.

Pros:

The detailed control of purchases based on past purchases/cost/vendor to have it flow back into the job bidding process to insure we are keeping on top of making sure we properly bid on work. Making purchases based on specific job requirements/needs is paramount to minimizing overhead that might get stuck in "stock" and left as an unknown costing thousands in underutilized inventory dollars.

Cons:

The difficulty in finding and/or tagging documents to certain jobs that might help the manufacturing process. This might be based on how your company uses related drawings or details for bids that might be won.

Ease of use enabling company control

Comments: Jobboss and ci employee’s help to create a supportive and easy to use product. Increasing efficiency and enabling execution of deliverables to the customer.

Pros:

Ease of use allows my business to execute at low cost overhead of my company

Cons:

That if the web browser get closed you lose unsaved work

User Friendly and Easy to Navigate

Comments: JobBOSS² is very user friendly and easy to navigate. It's fast and easy to use - there's no buffering, and we like that the system is web based.

Pros:

Estimating is great. Shipping and Purchasing are great. Inventory Control is great.

Cons:

Scheduling can be difficult to figure out, but we are working on that. Also, the Accounting can be a little wonky sometimes in how it integrates with QuickBooks.

Excellent Software

Comments: Overally, we like JobBoss and would recommend it.

Pros:

This software is very intuitive and easy to use. It's critical to our quoting, job cost tracking, billing, and purchasing.

Cons:

We don't have any real complaints to speak of.

Ease and efficiency

Comments: JobBOSS was a seamless transition. The team they have dedicated to your implementation is bar none the best.

Pros:

Very easy to use cloud based system. Access to the sysytem from anywhere

Cons:

That I did not purchase this software sooner.

Great application

Pros:

It's a great software which I have liked most. It's a user friendly

Cons:

Some of the futures are need to be improve

ECI Software Solutions Response

last year

Thank you for your kind feedback! We're glad you're happy with JobBOSS² and that it's been helpful for your business. Thank you for also sharing that there could be some improvements. I'd love to hear more about them. Please email me at [email protected]. Thanks, Fengning Yu JobBOSS² Product Marketer

Archaic & Tedious

Comments: Archaic and Tedious is exactly how I would describe Exact JobBoss. There are significant limitations in the software to consider up front. Part numbers are limited to 30 Characters. Drawing numbers are limited to 16 characters. General Description field is limited to 30 characters. Their answer to this is to provide an extended description dialog box. But you can not see the value of extended description in any sort of list view, therefore you can not see the complete description of your materials or parts anyplace until you generate quote document, or purchase order document, or a report. The general Description field will clip your description. It will let you enter more than 30 characters. But if you save and exit, then open the same quote it will have clipped the description to 30 characters. The UI is not user-friendly despite other reviews. I seriously doubt they have conducted usability and ergonomics studies with actual customers. It is very easy to get off track and be very disorganized with materials. Where it should have a good predefined material structure. The reporting side is very limited unless you are familiar with programming Crystal reports yourself. If you are building a product structure where multiple components use the same material, there is no way to add the same material to multiple components at once. You can copy material from one component to another, however, you cannot copy just a single material. For example, the component that I am copying from may have 5 materials in it. I have to copy all 5 materials into the target component then delete the materials I don't want in it. Same way with copying routings. A tech support rep argued this with me via email. To convince him I was correct and it was not possible I had to take a video of my screen attempting to copy one material and send that to him. Only then did he come off his position that it was possible. I can not see both the routings of a component and the materials of a component at the same time. They are two separate view windows you have to click back and forth in. Likewise, you cannot see the materials in multiple components at once. You have to click back and forth between the components you are interested in. If they rearranged their UI you could do some of these things, because there is plenty of room on your average size monitor screen. I have a 24" monitor and at a comfortable resolution, JobBoss is really only utilizing about 50% of my display space with actual pertinent information and controls. It's very easy to accidentally delete things and there are not many places where you can Undo, so if you accidentally delete something you are SOL. There is no way to add additional custom properties to a component. For example, I can not have Customer Part # and Our Part#. There are unforeseen nuances as well with formatting as well. If you enter a value in Vendor Reference field or Detail Number, then it overwrites the space for Extended Description on our Purchase Orders with Vendor Reference or Detail Number instead. You can not delete a material that has been used in a job. Unfortunately, we have a terrible material database with poorly named materials. We would like to replace the badly named materials with new materials that make more sense. But there is no good way to do this. Once a material has been used, closed, or scheduled it can not be deleted. It can only be inactivated. But what I want to do is replace it completely. Now they will say that they have a replace functionality, but it is really a rename functionality. But you can only rename one material at a time. So it's not really a replace function. Lastly, if you have limited seats you can set a user sign out after a period of time. However, I have found that if you walk away and have not saved your quote or job and it auto signs you out, it DOES NOT always save it for you. So you may lose work that you have done since last save.

Pros:

It has quoting, materials, costing, and scheduling, and job status capabilities.

Cons:

Sadly the UI is severely lacking. And it seems not much thought is given to usability and efficiency.

ECI Jobbos Software is Non Intuitive and non flexible, and the Trap you into a year contract

Comments:

The software is probably the most poorly developed and an un-useful software that I have ever experienced. The product was complete and absolute garbage. I should have fire the employee who spec'd it in.

The implementation in trying to get the software to do what we wanted was a nightmare, so after 9 months of trying to "tweak" the system to do what we wanted, and another 2 months of just trying to live with what we bought, I decided to cut our losses. And then less than 10 days prior subscribing to the software for a year, I received an email telling me that my license key would be expiring, from which I was able to deduce and then confrim after contacting customer service, that we were on an annual contract.

And then without any call back number or anything I received an email telling me that I was required to cancel the contract 30 days prior to the "renewal", and therefore I could not cancel the annual renewal. (note I was paying monthly and frankly had no idea that this was an annual contract) Nonetheless I did contact them prior to the renewal once I figured out what they were pulling. For clarification, the email I received 10 days prior to the "renewal" did not reference "Renewal" or annual contract and it was sent to me 10 days prior so according the 30 day notice requirement, it was already to late as it were.

Pros:

Absolutely Nothing. There was nothing that we liked about the software

Cons:

The Description field for parts is limited to 30 characters. The database does not include a vendor/manufacturing part number field as a standard filed and you have to do workaround to get it to show on your purchase order. The software is completely non-intuitive, is extremely cumbersome and non-flexible and then they nickel and dime for every single change. The implementation phase was a total joke where after 9 months it still was not doing what we need it to do.. And then they to not make it clear that it is an annual subscription and that you need to provide a 30 day notice prior to renewal which they do not even inform you that it is a renewal. They simply tell you a few days ahead of time that you need to upload a license key.

Everything you ever NEEDED to know

Comments: E2 manages ALL your data from your shop floor through your bookkeeping. The reports have always been the best selling point. Even sorting data becomes easy with the various export methods. You can quickly transfer the report dat to say excell and then again manipulate and massage as need for even more insight. I have always (and will continue to) recommend this sofware to other owners.

Pros:

This software has the ability to organize your business workings into manageable reports. Reports that you can tailor to you specific needs. The more you follow the simple rules of E2, the more benefits it can deliver. In my own business no two jobs are alike and no procedures for the jobs are identical yet E2 understands this principle and manages to sort data in such a clear manner as to help you with decisions going forward on all future work. I cannot give a higher recommendation on any other similar system.

Cons:

1.) I wish I could control the "Markup Pct." column in the General Tab when entering parts. I feel this item should have strict control - administrator only! Any of my people entering a part has the ability to change this percentage at will. Many an argument has resulted from my becoming aware of someone making an adjustment to this column, I wish I could lock it! 2.) When processing a return, it writes back to the original Order and amends it. Now the "Order Total" changes. It should not change. The order total should still match the customer P.O. total. The simple code should be that the (Qty Ordered) X (Unit Price) goes to make up the (Order Total) UNLESS there is something in the 'Master Job Number' column. In this manner the customers P.O. amount would still match up to the Order Total

Finally moving away from E2

Pros:

The user interface is easy to understand and navigate. The routing and BOM functions work well. Outgoing paperwork (packing slips, vendor returns, RMAs...etc) are generated easily. The quality module works well for us. Ultimately its a great software for smaller job shops; ie, less than 25 employees.

Cons:

The scheduling system doesn't work. The system consistently puts out a schedule that doesn't make sense. We are a quick turn, CNC machining job shop, and need a software that enables us to understand our capacity. Often times, jobs that are due tomorrow are on the second page of the report, and jobs that aren't due for 6 weeks are at the top of the list. We worked with tech support and cannot get a resolution. We implemented E2 in 2003 and only started trying to use the scheduling module in the last year. It was a great software initially, but now that we have grown we need software that does what we need it to do. Beyond that, items frequently go corrupt. Unprocessing and reprocessing anything (work orders, purchase order, NCs, CAPAs...etc) risk corrupting the file. If you double click on certain things the system crashes. If two people are in an item at the same time, quantities and/or lines duplicate. Once supplies are received or product is shipped, the system will not allow certain changes to be made. The personnel efficiency reports generate numbers that don't make sense. We've visited this repeatedly and cannot sort out a solution. Just last week I reviewed the efficiency reports for our production crew, and a job they were given 4 hours to setup showed "ESTIMATED SETUP" time of 2.27 hours. Our settings are correct but for some reason the system comes up with understated estimates, despite what we tell it to do.

I no longer wanted my shop to run me....

Comments: E2 has been great to work with from the very beginning. We do not have an IT department but they helped walk me through the steps of setting up our system. They are always very nice and polite on the phone whenever I have to call. The system is great, with only a few bugs.

Pros:

The way that E2 links all the different aspects together with various search functions. I can easily find ANYTHING i'm looking for and run so many reports to find out whatever information I want.

Cons:

We still use the Access database version and it's only for PC. Two of us are dedicated Apple users, so that took some figuring out how to continue using Apple products with E2. There are only two reasons I haven't switched to the online hosted version - document type linking, and stable internet service.

E2 Team

Comments: E2 ShopTech has a great team to work with when your troubleshooting. If they can not find the answer they will make a copy of your database and find the answer and let you know the results. [SENSITIVE CONTENT HIDDEN] proved this to me on my last ticket sent in. Thank you for all your help troubleshooting the cost report vs the inventory stock amount.

Pros:

Easy use for an ERP System. I enjoy all the help and support when I was leaning this software a few years ago. the transition from the old software to the new software was very easy. Your team is very helpful when teaching others how to use the software. The classes are a huge help. Thank you.

Cons:

I could see improvement in offering the old live classes in the old E2 software. My old job, I used the old software then transitioned my team to the new we based software. Now, I am back using the old software until I move them to the web based software, and the classes are only in the new web based software, so it is difficult to teach a new team how to use this software when the video's only show the new web based version.

E2 Shop System Review

Comments: See my answer under "Pros".

Pros:

The software is very easy to learn and the interface is extremely easy to navigate. The modules provided exactly mirror the processes in our business so almost every part of the software is applicable to our day to day operations. Having our business data archived, accessible and organized has sped up and simplified many of the tasks that used to take much longer. Estimates are now completed much faster and processes such as material receiving, shipping or the production of purchase orders for our vendors have become standardized and much easier to do. The time savings and insights into our business / production processes have made us more competitive and our customers (especially our larger industrial customers) see value in the advantages we've gained from the software.

Cons:

The one part of the software that we find of little value is scheduling. This may not be the case for other users but as a job shop we've found that the scheduling module simply doesn't work with the realities of our production processes.

Good for Shop Management, Has Some Quirks

Pros:

-This system does work well for managing active jobs as well as keeping all the historical information on jobs run in the past. It's easy to look up jobs in the system, see how much you've charged in the past, see what machines you ran it on, see how many times you've run it, etc. -The visibility between the shop and the office is very helpful - we use the data collection function, and the office can look at any job and see where it's at in process and who has scanned into the job. -System links well - you can capture labor, material, machining and outside services all on the same job easily and efficiently. -Integrates well with quickbooks for invoicing. -Customer service is easy to contact and fairly knowledgeable (some reps are better than others, sometimes I've had to call multiple times for the same question but I do eventually get an answer) -System design is clean and straightforward.

Cons:

-The system has a lot of quirks that you can work around but just seem inefficient (ie you can't make a machine or work center inactive. This doesn't make sense for shops that upgrade machines and get rid of old or malfunctioning ones.) -The reports are helpful to a point - basically they are helpful if all of your information is entered exactly how JobBoss requires it to be entered. Sometimes you don't know you are entering something wrong until the report comes up looking very wrong, and it can be tricky to figure out where your settings need to be adjusted for the report to come out correctly. Once you know how to run everything, it's easy to repeat.

Growing Our Business

Comments:

Seventeen years ago I was brought into CAMCO to research and implement a comprehensive business and shop control solution for them. Other previous attempts to do so weren't working out and then we found Shoptech. I'm still here!

Shoptech has enabled us to control and track the hundreds of jobs and thousands of associated parts that flow through our business monthly. We can see where our time and materials are and have a precise breakout of costs and income. The accounting and reports module generate all that is needed for our accountants to do their respective tasks and give upper management the oversight they need to run the business.

Pros:

We're a growing company and as such have turn-over and new personnel growth. E2 is intuitive and our new employees seem to be able to adapt into the system with minimal effort and training. As the IT person here I have witnessed that peer-to-peer training seems to be all that is required to have that new person up and running on E2 within a short time and with little involvement from me, that's a big help! From Shipping and Receiving through final Billing, if our new hire has basic computing skills, their transition into that respective E2 function hasn't been a major training concern.

Cons:

We're a service and repair facility and it took considerable effort improvising and rethinking to adapt the system into our way of doing things. Initially the software seemed to be over-kill and confusing for our needs but with time we were able to merge our methods with the system and adapt.

Comments: We are a small third-generation custom sheet metal fabrication shop that has garnered a reputation for high quality, honest work, and trying to help all of our customers meet their increasingly shorter delivery times. Before E2 Shop System, we were using an outdated custom-written software for the Mac and updating that software into the 21st century was proving difficult and expensive. One day I received a mailer from ShopTech that said ''Are you controlling your shop, or is it controlling you?'' I thought to myself 'Isn't that the truth!!' So I called the number and talked to Greg in sales and after much consideration, we made the leap to the windows-based E2. It took approximately one year to fully migrate over to E2 once all the new hardware was set-up. I believe it could have been faster if we had an actual IT person. That being said, I'm not trained in IT, nor had much experience with Windows, but E2 was fairly easy to set up. It does take some getting used to, mostly because people are used to other software and have to make the mental switch, but once you figure out how everything ties in together, it's easy. The tech support staff was fantastic in helping me set up a windows server and they connected me with another customer that had done the same thing, which was extraordinarily helpful. We still use our Macs, but we LOVE E2 Shop System! My father even prefers the quoting method of E2 to the old custom program! It has allowed us to improve turn-around times on jobs and eliminated the constant bother of trying to figure out where jobs were in process in the shop. It has also improved our billing process; simplifying many tasks. It takes about 5 minutes to run the month end pdf reports for the accountant, vs an entire day of sorting actual paper in the old system. Everything is tied together and searching the system for just about anything is super-easy. I have customers call me all the time to look up information for them that they can't even find in their own systems. Our shop floor employees love being able to see what job they are clocked in on and eventually they will be able to know what job they should work on next. I haven't had time yet to delve into the wealth of data to analyze and quantify the exact benefit of E2, but just from our books, we can tell a marked increase in revenue, and we now can tell the actual real-time cost of jobs, rather than waiting until the next day's import. We have yet to harness it's full potential, since we are so small and focused on production, but there's only one way to go from here....up!!! Thank you SO MUCH to Janelle, Corey, Melissa, Greg and the rest of the ShopTech team that has helped me over the years. You have no idea how fantastic it is to call tech support and get the same, friendly, English-speaking, and knowledgeable people every time.

Excellent for job shops

Comments: I ran my business for the first year keeping everything in spreadsheets and building it as I went. Much of it was very disorganized. E2 allowed me to get all of my part numbers and material information into a database while being able to route and price and the same time. It also streamlined the processes of creating quotes, processing orders, processing shipments, and creating invoices by having it all integrated with the database. It has saved me countless hours of typing/copying in spreadsheets

Pros:

The database and pricing system are set up perfectly for the type of work I do: small-run, custom product manufacturing.

Cons:

It can be have a slight lag if the internet connection is less than optimal

E2 Shop System for a Job Shop

Comments: This software has all of the features necessary to quote a project, purchase for a project, and move the project successfully through the shop from one work station to another, accurately accumulating time as it goes. It will give you insight into your jobs as to estimated performance versus actual performance, it will give you control over your purchasing and a 30,000ft level view of your work center loading. Overall, it has the capabilities to meet a wide variety of manufacturing requirements with good reporting, and useful tools

Pros:

The software is pretty easy to use. We can usually get new employees up and running fully on the software with only a couple of days of training. If you implement the time keeping module it allows for excellent review of jobs and verification of timing for your work. By far the best part of E-2 is the support. They have a wide range of support tools including Webex training's, customer support, and even analysts who can help implement, and improve your software usage.

Cons:

Like most software it is built around a model that may not exactly match your business model. In this case the issue is Parts vs. Jobs. Our shop tracks jobs through the shop that are composed of multiple parts. E-2 works best if one part is one job. While it is possible to run multi-part jobs you lose some of the functionality of the software when you do. The other limitation is eliminating duplicate data. If you have customers, materials or parts that were duplicated, or just plain created incorrectly, it is cumbersome to remove them from the E-2 system.